Single sided PCB milling

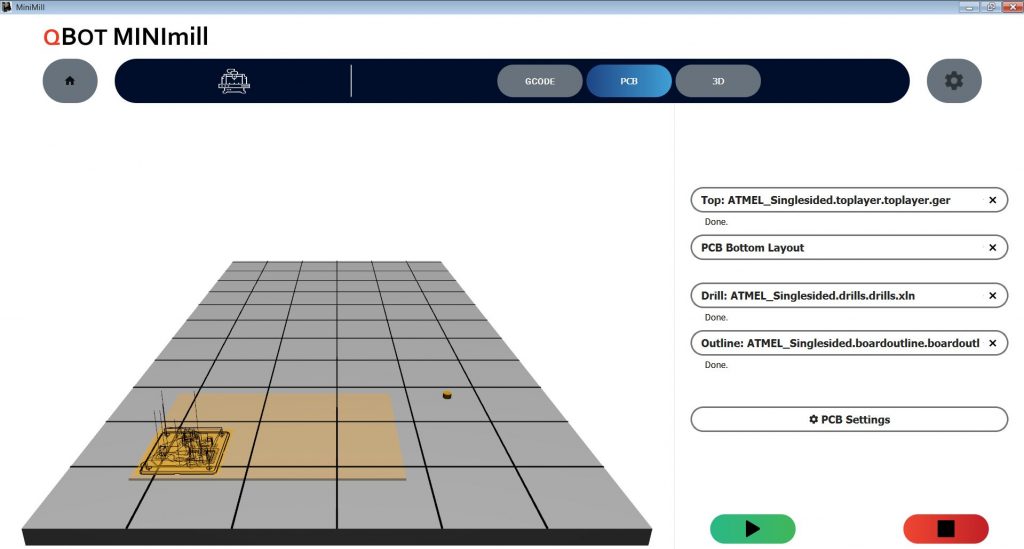

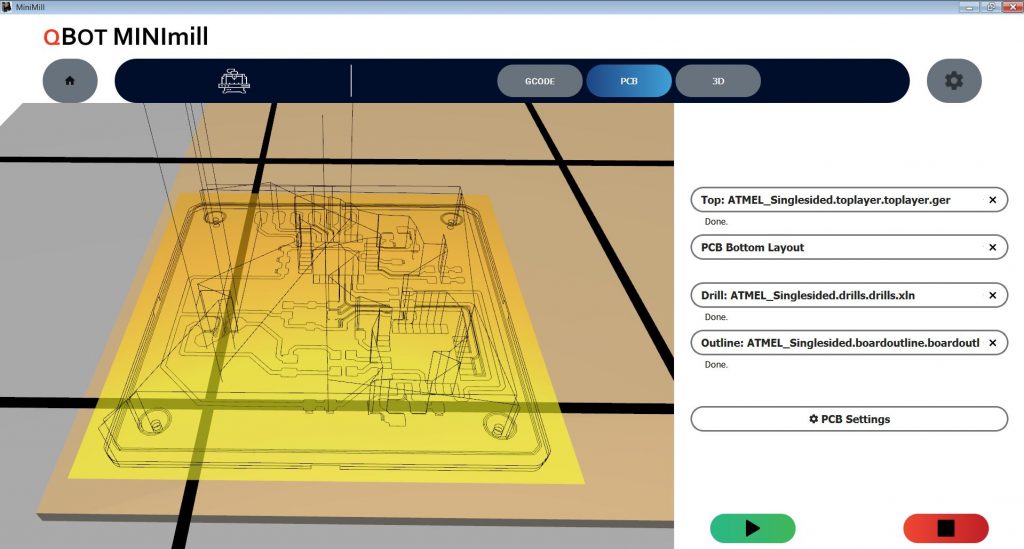

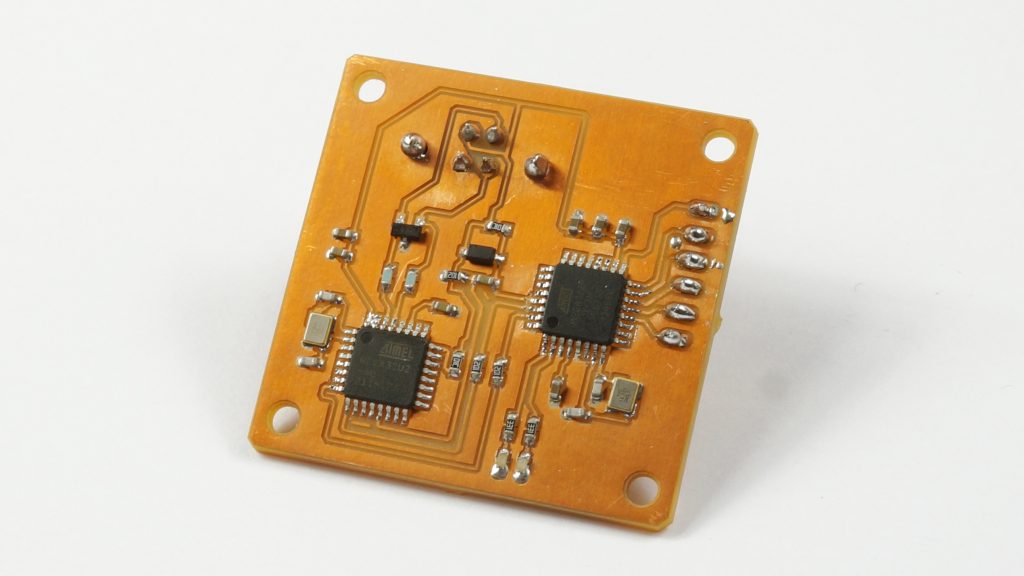

Your MINImill can manufacture single or double sided PCBs from GERBER files. The following tutorial covers single sided pcbs.

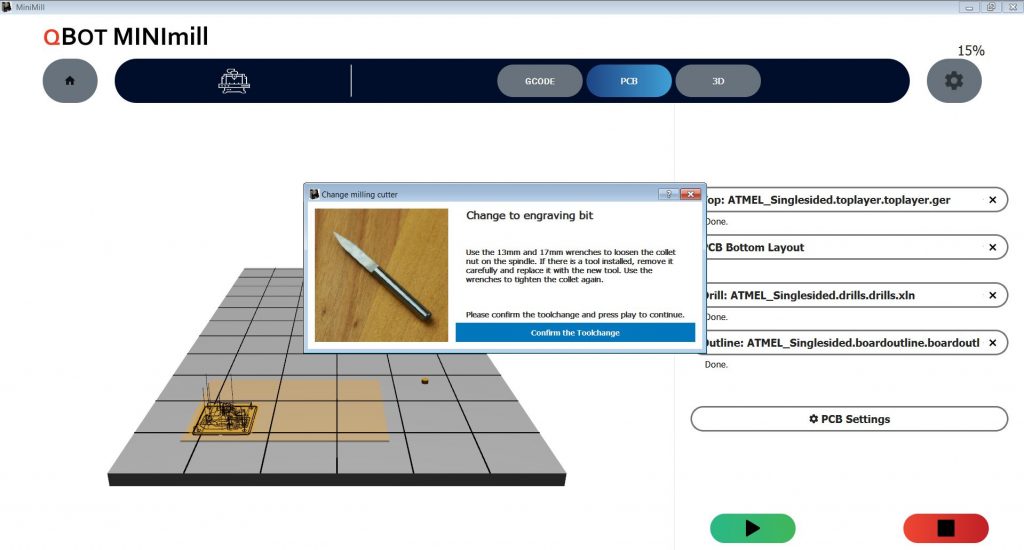

In order for the tool change and the automatic height adjustment to work with your MINImill, we recommend the PCB clamping holder. Alternatively, you can also connect the circuit board directly to the controller. The necessary wiring is described in the instructions for the clamping holder or the tool length sensor.

Deutsch

Deutsch