Automated Tool Change

The software supports manual and automatic M6 tool changes. Tools can be created, defined how the tool is picked up and put back. The T command specifies which tool will be used next.

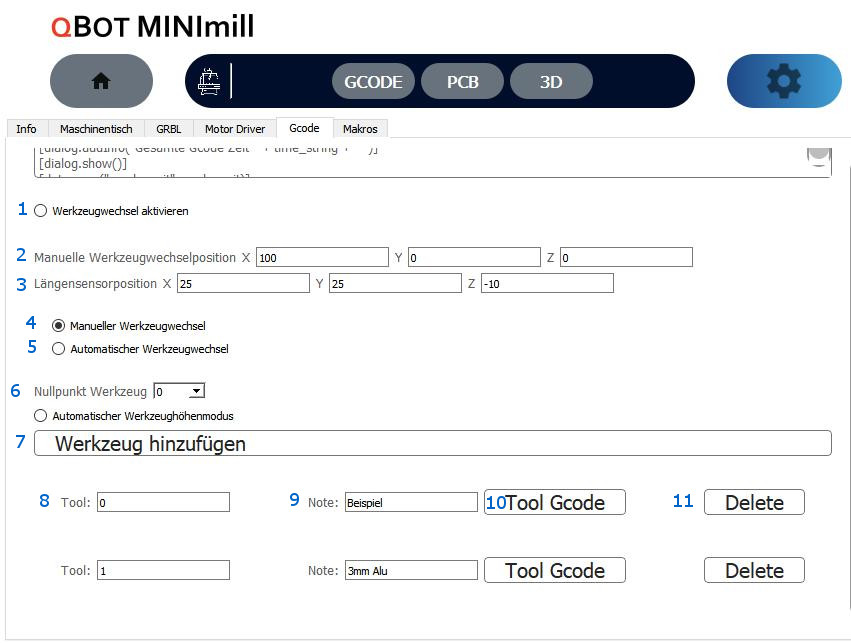

- Enable tool change

- Manual tool change position

- Tool Length sensor location

- Manual tool change

- Automatic tool change

- Automatic tool height mode

- Add tool

- Tools

- Note

- Tool Gcode

- Delete

If enabled, M6 is supported in Gcode

The machine will go to this position when M6 is triggered and Manual mode (4) is activated

Position of tool length sensor is used in tool height mode, also available in gcode script. Z indicates from which height the measurement can start.

M6 moves to the manual tool change position and prompts the user to change the tool, showing the note as well as comments written in the Gcode line of M6.

M6 puts back the current end mill and gets the new end mill as specified in point (12) and (13)

The tool is automatically measured, so a tool length sensor is required. The zero point of the workpiece is set with the zero point tool. This information is used to compensate for the different tool lengths.

This button adds a new tool.

Specifies the tool number which is used in the GCODE with letter T … M6.

Note displayed during manual tool change.

Opens the commands for how the tool is picked up and put back with the automatic tool change.

Deletes the tool

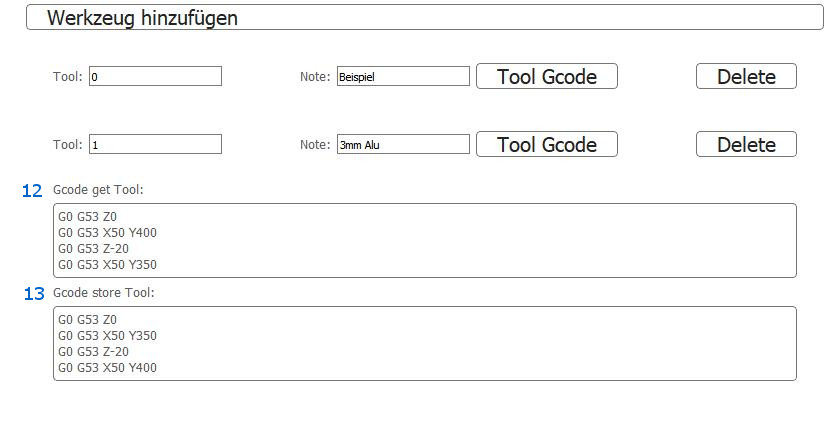

- Gcode get Tool

- Gcode store tool

Gcode commands that are executed when the tool is picked up with M6.

Gcode commands to be executed when the tool is put back.

Example

T2 ; Tool 2 is being prepared

M6;Tool 2 is picked upAfter a tool change, a tool length compensation could be calculated using a tool length sensor.

- Manual

- Automatic

- Altitude mode

Approaches the tool change position and prompts the user to change the tool.

Puts the current tool back and gets the new tool

like manual/automatic then the tool is measured on the length sensor and an offset is set so that the difference in length is compensated

Deutsch

Deutsch